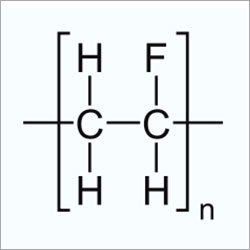

PVF Resin

PVF Resin Specification

- Type

- PVF Resin

- CAS No

- 24981-14-4

- EINECS No

- 607-457-0

- Grade

- Industrial Grade

- Purity(%)

- 99

- Application

- Industrial Coatings, Films, Insulation, Chemical Resistance Linings

- Color

- White Powder

- Form

- Powder

About PVF Resin

Features:

- High softening point

- Excellent in electrical insulation

- Superior in mechanical properties, adhesion, abrasion, Plasticity, heat stability & chemical resistance

- Available at competitive prices

Superior Chemical and Thermal Performance

PVF Resin stands out due to its exceptional chemical resistance and thermal stability, making it a preferred choice for demanding environments. Its high dielectric strength further ensures reliable performance in electrical insulation applications. This combination of properties significantly extends the longevity of products manufactured with PVF Resin, reducing maintenance needs and improving operational safety.

Versatile Industrial Applications

With its industrial-grade purity and robust physical characteristics, PVF Resin adapts to a variety of uses. It is widely employed in specialty coatings for equipment and pipelines, protective films, high-performance insulation materials, and chemical-resistant linings. Its ability to perform under harsh conditions makes it essential for sectors such as chemical processing, electronics, and manufacturing.

FAQs of PVF Resin:

Q: How should PVF Resin be stored to preserve its quality?

A: PVF Resin should be stored in a cool, dry place to preserve its physical and chemical integrity. Proper storage conditions maximize its 12-month shelf life and ensure it remains free from moisture or contaminants.Q: What is the recommended process for using PVF Resin in industrial applications?

A: PVF Resin is typically processed as a white powder and converted into films with thickness ranging from 10 to 50m. It is applied through specialized coating or extrusion techniques depending on the specific application, ensuring optimal adhesion and performance.Q: When is PVF Resin most beneficial to use?

A: PVF Resin is most beneficial in applications that demand high chemical resistance, excellent thermal stability, and strong dielectric properties. It is ideal for manufacturing coatings, insulation materials, and chemical-resistant linings in harsh or corrosive environments.Q: Where can PVF Resin be applied for maximum effectiveness?

A: PVF Resin excels in industries such as electronics, chemical processing, and manufacturing, where it serves in coatings for machinery, insulation for cables, and linings for chemical containers. Its versatile characteristics allow for broad use in environments exposed to heat, electricity, or reactive chemicals.Q: What are the main benefits of using PVF Resin in coatings or insulation products?

A: The main benefits include excellent durability, superior chemical resistance, outstanding thermal stability, and high dielectric strength. These features ensure long-lasting, reliable protection for industrial components and enhance the overall safety and efficiency of insulated products.Q: How does the purity and grade of PVF Resin affect its usage?

A: With a purity of 99% and classified as industrial grade, PVF Resin offers consistent quality and performance. This high purity level enables manufacturers to meet stringent industry standards, particularly where safety and durability are critical considerations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Synthetic Resins Category

Polyvinyl Butyral Resin

Price 500000 INR

Minimum Order Quantity : 1 Piece

Purity(%) : 99%

Type : Other, Polyvinyl Butyral Resin

Application : Laminated Glass, Safety Glass, Automotive Glass, Architectural Glass

Color : White

Liquid Resin

Price 200 INR / Unit

Minimum Order Quantity : 1 Unit

Purity(%) : 99%

Type : Synthetic Resin

Application : Flock printing & PVC Wood lamination

Color : Transparent

Butyral Resin

Price 100 INR

Minimum Order Quantity : 1 Piece

Purity(%) : 99%

Type : Synthetic Resin

Application : Industrial Coating, Adhesives, Printing Ink, Paint

Color : White

Urea Formaldehyde Resin

Purity(%) : 98% 99%

Type : Synthetic Resin

Application : Adhesives, Plywood, Particle Board, MDF (Medium Density Fiberboard), Laminates, Furniture Manufacturing, Coatings

Color : White / Milky White (depending on form powder or liquid)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry